The major hazards associated with electricity in the science laboratory that require some safety measures are electrical shock and fire. Electrical shockoccurs when the body becomes part of the electric circuit, either when an individual comes in contact with both wires of an electrical circuit, one wire of a live circuit and the ground, or a metallic part that has become live by contact with an electrical conductor.

ELECTRICITY RELATED HAZARDS

The severity and effects of an electrical shock depend on a number of factors, such as the pathway through the body, the amount of current, the length of time of the exposure, and whether the skin is wet or dry. Water is a great conductor of electricity, allowing current to flow more easily in wet conditions and through wet skin. The effect of the shock may range from a slight tingle to severe burns to cardiac arrest.

|

CURRENT |

REACTION |

|

1 Milliampere |

Perception level |

|

5 Milliamperes |

Slight shock felt; not painful but disturbing |

|

6-30 Milliamperes |

Painful shock; “let-go” range |

|

50-150 Milliamperes |

Extreme pain, respiratory arrest, severe muscular contraction |

|

1000-4,300 Milliamperes |

Ventricular fibrillation |

|

10,000+ Milliamperes |

Cardiac arrest, severe burns and probable death |

The table above shows the general relationship between the degree of injury and amount of current. While reading this table, keep in mind that most electrical circuits can provide, under normal conditions, up to 20,000 milliamperes of current flow.

In addition to the electrical shock hazards, sparks from electrical equipment can serve as an ignition source for flammable or explosive vapours or combustible materials.

PREVENTING ELECTRICAL HAZARDS

There are various ways of protecting people from the hazards caused by electricity, including insulation, guarding, grounding, and electrical protective devices. But first, the following care should be taken when dealing with lab work involving electricity.

(i) Inspect wiring of equipment before each use. Replace damaged electrical cables immediately.

(ii) Use safe work practices every time electrical equipment is used.

(iii) Know the location and how to operate shut-off switches and/or circuit breaker panels. Use these devices to shut off equipment in the event of a fire or electrocution.

(iv) Limit the use of extension cords. Use only for temporary operations and then only for short periods of time.

(v) Multi-plug adapters must have circuit breakers or fuses.

(vi) Minimise the potential for water or chemical spills on or near electrical equipment.

Insulation

All electrical cables should have sufficient insulation to prevent direct contact with wires. In a laboratory, it is particularly important to check all cables before each use, since corrosive chemicals or solvents may erode the insulation.

Damaged cables should be repaired or taken out of service immediately, especially in wet environments such as cold rooms and near water baths.

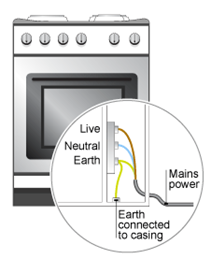

Grounding/earthing

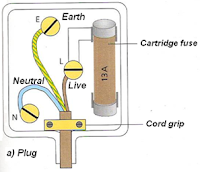

Only equipment with three-prong plugs should be used in the laboratory. The third prong provides a path to ground for internal electrical short circuits, thereby meeting the user from a potential electrical shock.

Circuit Protection Devices

Circuit protection devices are designed to automatically limit or shut off the flow of electricity in the event of a ground-fault, overload or short circuit in the wiring system. Circuit breakers and fuses are two well-known examples of such devices.

Fuses and circuit breakers prevent over-heating of wires and components that might otherwise create fire hazards. They disconnect the circuit when it becomes overloaded. This overload protection is very useful for equipment that is left on for extended periods of time.

SAFE WORK PRACTICES

The following practices may reduce risk of injury or fire when working with electrical equipment:

a. Avoid contact with live electrical circuits.

b. Use guarding around exposed circuits and sources of live electricity.

c. Disconnect the power source before servicing or repairing electrical equipment.

d. When it is necessary to handle equipment that is plugged in, be sure hands are dry and, when possible, wear nonconductive gloves and shoes with insulated soles.

e. If it is safe to do so, work with only one hand, keeping the other hand at your side or in your pocket, away from all conductive material. This precaution reduces the likelihood of accidents that result in current passing through the chest cavity.

f. Minimise the use of electrical equipment in cold rooms or other areas where condensation is likely. If equipment must be used in such areas, mount the equipment on a wall or vertical panel.

g. If water or a chemical is spilled onto equipment, shut off power at the main switch or circuit breaker and unplug the equipment.

h. If an individual comes in contact with a live electrical conductor, do not touch the equipment, cable or person. Disconnect the power source from the circuit breaker or pull out the plug using a leather belt.

i. Repairs of high voltage or high current equipment should be performed only by trained electricians.